Sub micron defect sensitivity

First system in the world to do wafer 3D & 2D analysis simultaneously

- Increase your yield with the most advanced A.I. in semiconductor metrology.

- BTBP's system detects and quantifies process defects.

- Wafer metrology is the key to process control and yield enhancement.

- Load & scan the wafer.

- Capture the full wafer for 2D and 3D analysis.

- Recipe setup and binning capability.

- Classify wafer defects and generate highest resolution 3D models for quantitative measurements.

- Detect & display defects like particles, scratches, missing patterns & bumps.

Highlights

DETECTING THE DEFECTS

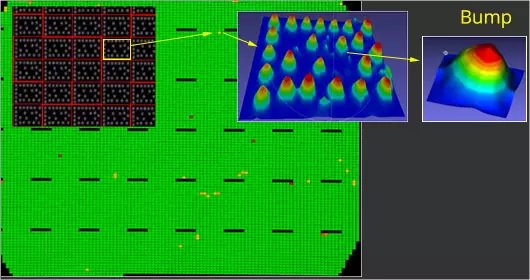

Bumps on the wafer:

- Identifying X, Y location(relative to notch), minimum height, maximum height, average height and diameter of the bump on a wafer.

- Information is saved in the industry standard KLARF format.

BINNING CAPABILITY

- Missing bumps can be identified.

- High quality imaging providing greater detail of intensities for detecting even floor variations & the height of bumps more accurately.

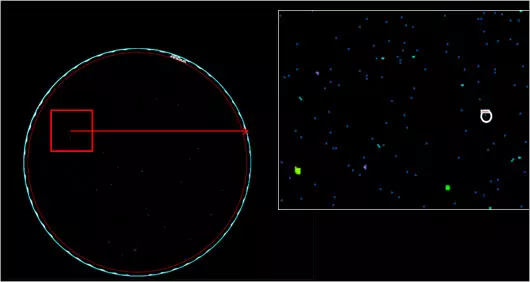

PARTICLES ON WAFER

- Features capable of detecting the presence of particles, residues, damaged wafers, wafer edges, hard & soft defects with their locations, count and size with high binning accuracy.

- 32 Bit High Dynamic Range Process of Scanning: Provides a wide range of intensities for detecting sub micron particles (0.25 microns) to very large particles (many millimeters) with a single scan for front and back of the wafer.

- Automatic classification of defects through our computer algorithm process of deep learning(A.I).